VMAT OPTIMIZATION IN RAYSTATION

RayStation VMAT allows for VMAT plans to be created in a similar way to fixed beam plans. The beams are replaced by arcs, and there are some additional settings regarding delivery time and motions constraints. Otherwise, the optimization functions and the interface are the same. The optimization process follows the same pattern as for SMLC optimization: a preliminary fluence optimization step, sequencing into machine parameters followed by direct optimization of machine parameters. Varian, Elekta and Siemens machines are supported, including non-upgraded Varian machines and the Siemens mArc.

OPTIMIZATION STEPS

This section describes the steps performed during an optimization of a single arc VMAT plan. With multiple arcs there are a few differences that are described in a later section.

Algorithmic details

1. Initial fluence maps are generated at the start and the stop angle, and at 24 degree increments from the start angle. The fluence maps are initialized to the target projections.

2. The fluence maps are optimized resulting in one fluence profile per initial angle.

3. At the sequencing phase, the optimized fluence maps are converted into arc control points distributed over the entire arc.

I. The fluence maps are converted into 2–4 control points each using a leaf sweep style sequencing.

II. The smallest control points are filtered out to leave 2 control points per initial angle. These control points are distributed to adjacent gantry angles. A sorting algorithm determines where to put each control point to minimize overall leaf travel for the arc.

III. Control points are then added to achieve the desired final gantry spacing. This is done by cloning the control points that result from the conversion.

IV. Before optimization starts, all control points are processed to comply with the motion constraints of VMAT: max leaf speed, valid dose rates, delivery time. This often means that leaves are shifted.

5. Machine parameter optimization is performed on all control points taking all applicable machine and user constraints into account.

6. Finally, jaws and passive leaves are positioned. For machines with static jaw behavior the jaws are conformed to the union of the segment shapes. For machines with dynamic jaw behavior the jaws are conformed to each segment shape taking the maximum jaw speed and other relevant constraints into account.

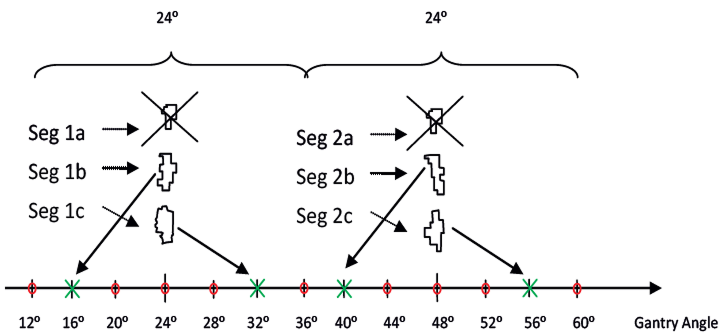

Segment filtering and redistribution

Illustration of segment filtering and redistribution. In this example the optimized fluences at the initial directions 24º and 48º are converted into 3 control points respectively, where one control point is discarded and two are repositioned (green x). Additional control points created by cloning are distributed to achieve the desired gantry spacing (red circles).

MULTIPLE ARCS

It is possible to optimize more than one arc simultaneously. This can be done in two different ways – either the properties of all arcs are user defined, or the dual arc feature is used.

User specified multiple arcs

In RayStation, it is possible to define any number of arcs, the properties of which can be individually selected. Therefore the arcs may cover different gantry angle intervals, rotate in the clockwise or counterclockwise direction etc.

All arcs are treated as individual arcs and optimized simultaneously. If two arcs cover the same gantry angles, it is likely that the fluence profiles of the two arcs at sequencing are very similar resulting in similar apertures around the arc, which is not an optimal starting point for the optimization. Therefore this feature is primarily useful when multiple arcs with no or limited overlap are desired.

For machines where jaw motion can be switched off, it is possible to create multiple arcs that cover different parts of the target (or different targets) by manually setting the jaws prior to starting the optimization.

Dual arcs

Another way to create a multiple arc plan is to use the dual arc feature, whereby a second arc will be created during the sequencing stage. The first arc rotates in the selected direction and the second in the opposite direction. In this manner the gantry does not need to be reset before delivery of the second arc.

Only one set of fluence profiles are optimized for an arc selected to be optimized as a dual arc just as for the single arc case. At sequencing, about 5 control points are created for each initial angle compared to the 2–4 for a single arc, keeping more information from the fluence maps. One or two control points from each initial angle are assigned to each arc according to an algorithm that both considers the ‘centre of gravity along the x-axis’ of each control point and the leaf travel. This to a large extent generates one arc where the leaves are distributed to the left and a second where they are distributed to the right in the MLC, in a way that simultaneously minimizes the leaf travel.

There are advantages to this strategy when an organ at risk such as spinal cord or rectum divides the target in a left and a right side. If a single arc is used, control points both to the left and to the right of the OAR are created to make sure that the target coverage is met. The leaf openings must in this case travel back and forth over the OAR increasing the dose to the OAR. Using dual arcs, one arc will focus on the left side of the target and one on the right side, reducing the leaf openings over the OAR and thereby the dose delivered to it.

CONCLUSION

RaySearch’s proven VMAT treatment planning algorithm is the most flexible solution available today, allowing clinicians to create single or multiple-arc plans for Elekta, Varian and Siemens linear accelerators.

REFERENCES

K. Bzdusek, H. Friberger, K. Eriksson, B. Hårdemark, D. Robinson, M. Kaus. Development and evaluation of an efficient approach to volumetric arc therapy planning, Medical Physics 36(6):2328-39, 2009.

For more information or to see a demo, contact sales@raysearchlabs.com